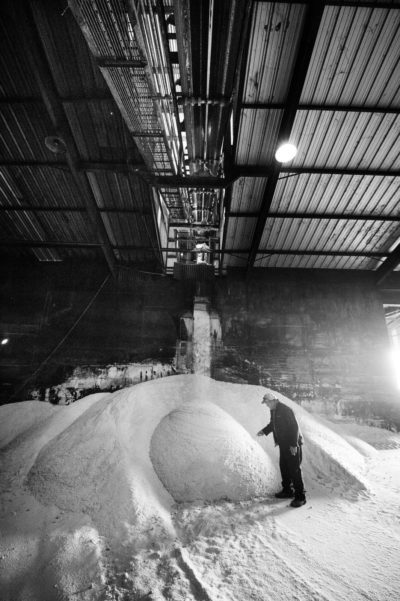

Ourso Sugar Cane Farm

Sarah Ourso Giroir, one of my wedding clients who married at Nottoway Plantation on July 27, 2012, first asked me to do a black & white photography project documenting her dad’s life as a sugar cane farmer, one of the largest in Iberville Parish, including all stages of cane production. I immediately jumped at this opportunity and decided to make it a personal project since my normal photography business Eye Wander Photo is entirely based on portraits and weddings.